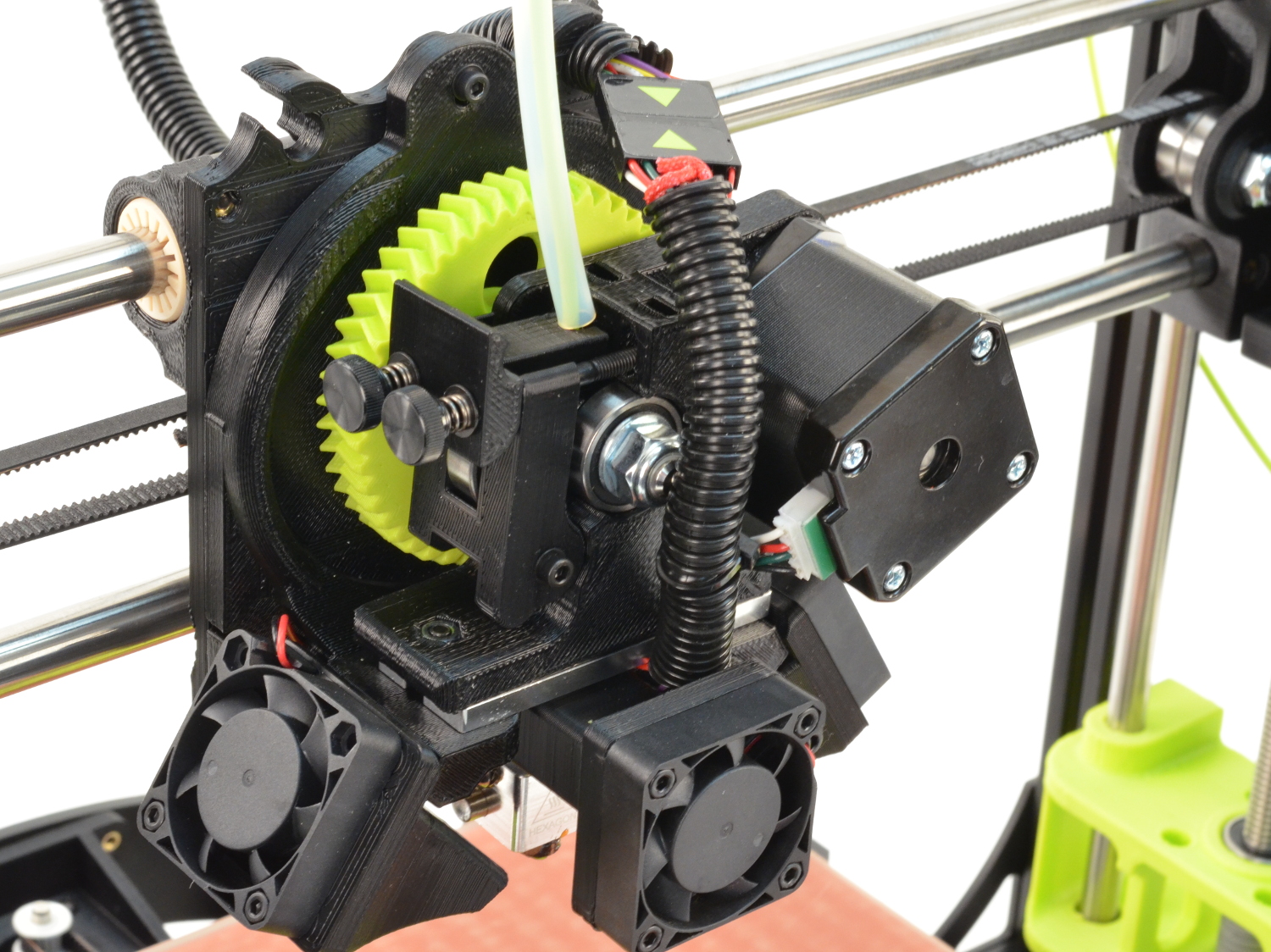

TAZ 6 Single Extruder v2.1

0.50 mm nozzle diameter

Compatible with non-flexible filament with an extrusion temperature under 300°C

These Cura profiles are no longer being updated and are only compatible with Cura LE v21.08 and below. Users are encouraged to use the latest version of Cura LulzBot Edition as these pages will be used as a point of reference for archival purposes only.

Cura LulzBot Edition is a Free Software program that both prepares your files for printing (by converting your model into GCODE), and also allows you to control the operation of your LulzBot 3D printer. Beginner users are advised to use the Quickprint View in Cura.

Advanced users can do more by scrolling down this page for LulzBot TAZ 6 print profiles, developed and tested by the LulzBot team to ensure the best performance out of your LulzBot 3D printer.

To get printing right away, the default LulzBot TAZ 6 print profiles listed below can be imported into Cura LulzBot Edition for ready-to-print settings. To download and save the configuration file, right click and select Save As.

In order to use the print profiles below you will need to switch to the Full Settings view (Expert > Switch to full settings). After downloading, import the Cura print profile by selecting, in Cura, File > Open Profile. Navigate and select the pre-set Cura print profile file of choice.

0.50 mm nozzle diameter

Compatible with non-flexible filament with an extrusion temperature under 300°C

0.60 mm nozzle diameter

Compatible with flexible filament with an extrusion temperature under 300°C

1.20 mm nozzle diameter

Compatible with non-flexible filament with an extrusion temperature under 300°C

The following filament options perform well at larger scales.

The following filament options may be challenging to print at larger scales.

0.50 mm nozzle diameter

Compatible with non-flexible filaments with an extrusion temperature under 300°C

0.60 mm nozzle diameter

Compatible with both flexible and non-flexible filaments with an extrusion temperature under 300°C

From: colorFabb.com

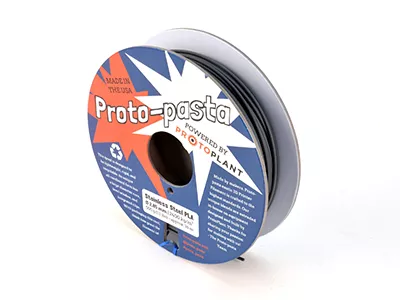

A special point of attention is the abrasive nature of the carbon fibers. In general these fibers will accelerate the nozzle-wear of brass nozzles, much faster than unfilled filaments. Therefore we recommend to use nozzle’s from Stainless steel or hardened copper alloys.

While it's tempting to try using filament containing carbon fiber, many users are reporting trouble extruding after using that material, even from different vendors. We've seen people that wear out the inside of their nozzle, not to mention having lingering extrusion issues after switching to more common filament types. One of the benefits of carbon fiber containing materials are it's strength, similarly to good quality plywood. The interlocking long carbon fiber strands give the material a super-strong core. All the filaments we've seen so far however, don't have that same kind of long carbon fiber strands, so your prints are similar to Oriented Strand Board (cheaper plywood with smaller fiber length), which isn't as strong or as durable. That somewhat defeats the purpose of using carbon fiber materials. We find that for applications needing high-strength printed parts Nylon is a great material. While a bit slower to print, the parts are much, much stronger.

Speed: In general, the slower at which you print, the finer your surface finishes will appear.

Support: Support material can be printed with the same extruder and filament. It can be easily removed and set to be automatically generated or turned off completely. Generally, you can print without support material provided that any overhanging sections are less than 45 degrees.

Layer Height: The layer height determines how visible each layer is in the resulting model. The larger the layer height, the faster the print. Larger layer heights are more forgiving, while finer layer heights will take longer and need to have the various hardware and software settings balanced. However, finer layer heights will provide a smoother surface.