For some makers, the revelatory empowerment of desktop 3D printing arrives at just the right time, altering the shape of their dreams as well as their designs to create compelling 3D printing stories. John Kray recently signed his first business lease for a shop space as the young co-founder of Hydra Research, LLC, an additive manufacturing and technology startup based in Portland, Oregon, USA. Understandably, he’s still a bit shocked at the speed of change since his first LulzBot Mini arrived in 2016.

“This is all a little overwhelming as I just graduated college less than 5 months ago, but at the same time I’ve never had more fun [while] doing something that felt as rewarding as starting this small company has been,” Kray said. “I'm totally serious when I say this, I probably wouldn’t have even thought of doing this if I hadn’t gotten the [LulzBot] Mini and been able to modify it so much and so easily. Getting that printer really sparked this whole journey I’m on right now.”

As an undergraduate in physics, Kray became fascinated with the possibilities of 3D printing and purchased his own LulzBot Mini when the “price and degree of accessibility” were too good to pass up on. “I was watching a bunch of YouTube videos, including xrobots, Thomas Sanladerer, and the 3D Printing Nerd among others, and couldn’t get the idea [of] making my concepts into real objects out of my head,” Kray said. He was working at a local coffee shop at the time and identified the worn, rubber handles on the espresso machines as ideal testing opportunities for making WoodFill 3D printed replacement parts using his LulzBot Mini 3D Printer.

“I chose the [LulzBot] Mini because of the robust build quality, ability to print almost any material, and LulzBot’s dedication to Open Source,” Kray said. “The results were better than expected… the handles were sanded, stained, and lacquered, and have held up very well [against] the abuse of a very busy cafe environment.”

The success of the WoodFill replacement handles encouraged Kray and his classmate-turned-business-partner, Griffin Carey, to begin a 3D printed replacement parts service where customers can order high quality prototypes, models, and usable parts online.They have since gone on to develop and sell their own custom tool head for the LulzBot Mini, the LM Nano, equipped with an E3D Titan Extruder to print rigid, flexible, and abrasive materials.

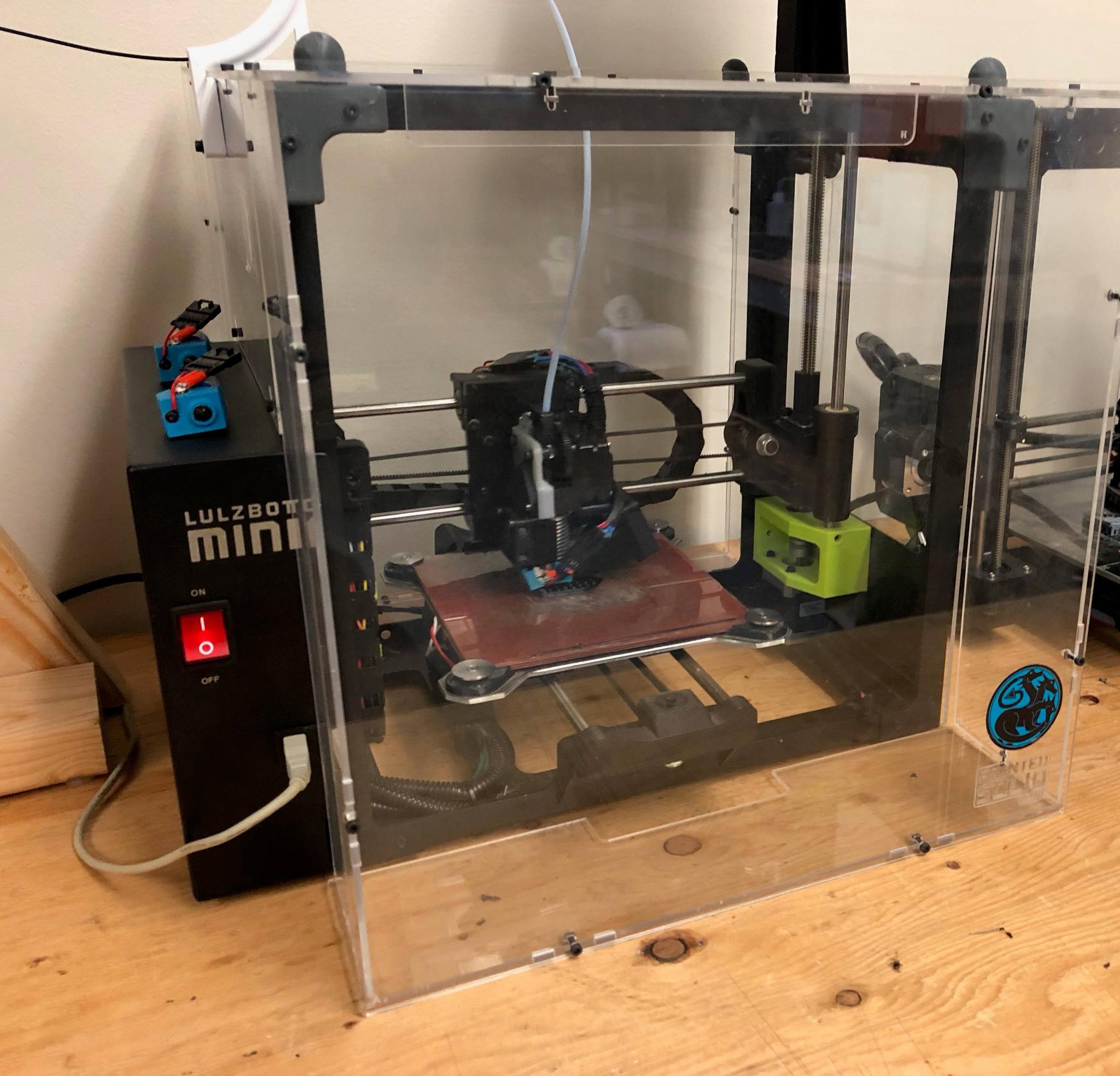

Backed by a LulzBot TAZ 6, a LulzBot Mini, and an open business philosophy that mirrors Aleph Objects’, Hydra Research embraces progress as a collaborative effort, publishing the source code for all their products under the Creative Commons Attribution-ShareAlike 4.0 International License.

“LulzBot's commitment to Open Source software and hardware have really made the Mini a great tool as it's easy to work on and fix ourselves, as well as make our own modifications,” Kray said. “I spend a lot of time on the LulzBot OHAI page [and] in the development documentation. ... If we haven't hit 1,000 prints on the [LulzBot] Mini yet, we are getting very close.”

With advanced manufacturing technology now readily accessible to dreamers like John Kray, there's no need to keep holding a finger in the air, waiting for the wind to change. Choose tools you can trust, set sail, and make everything.

Explore More 3D Printing in Open Source Communities ➡

Photos licensed CC BY-SA 4.0 International © Hydra Research, LLC.

Note: Any damage from installation or use of third-party accessories is not covered under the LulzBot Warranty.