As the world-leading producer of lacrosse helmets, Cascade Lacrosse uses industrial-grade LulzBot 3D Printers to stay on top and bring new ideas to market quickly. Reliable prototype production techniques have not only improved internal processes, but also enabled Cascade Lacrosse to drive innovation in the industry while producing high-quality products that keep players safe and comfortable.

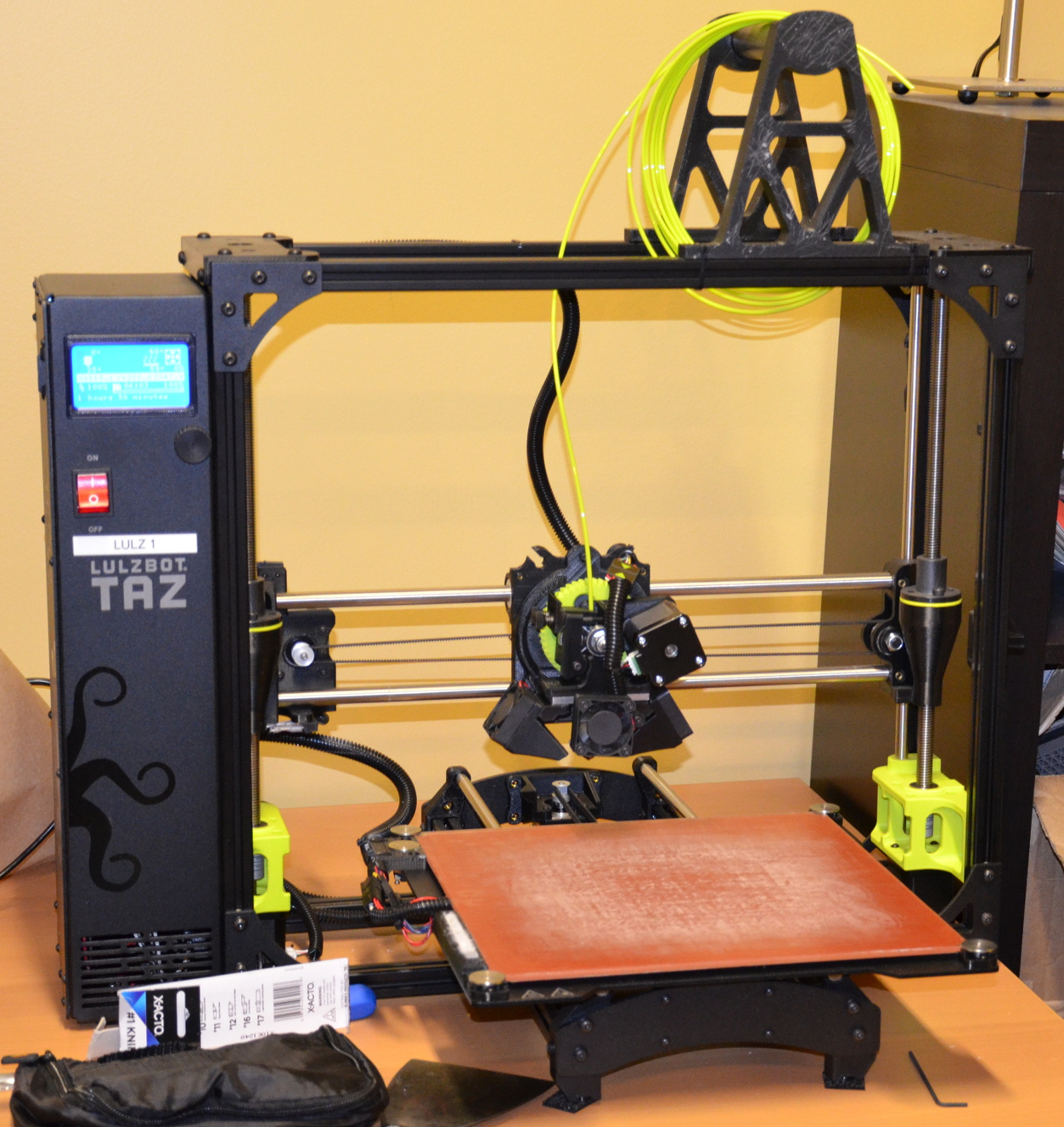

“The LulzBot 3D Printers brand name kept coming up as an industry leader in quality and customer service when doing research,” Chris Laurita, product developer at Cascade Lacrosse, said. “The ability to print flexible material using its Flexystruder Tool Head made choosing the LulzBot TAZ 3D Printer an easy decision for us.”

“Any part on our helmet that is flexed or needs some squish to it gets printed on one of our LulzBot TAZ 3D Printers with a Flexystruder Tool Head,” Laurita said.

Adding LulzBot 3D Printers to the prototyping process supports Cascade Lacrosse as they develop new products and stay in the lead. They redefined the category of women's lacrosse equipment with the introduction of the Cascade LX, and they are using 3D printing to push the category even further.

Their success has also opened the door to collaboration for sister companies Easton Baseball, BAUER Hockey, and Maverik Lacrosse, with Cascade engineers sharing their knowledge across the organization.

In terms of the user experience with LulzBot 3D Printers, Cascade Lacrosse appreciates the readily available technical support and the longevity of the machines.

“The couple times that we have had issues with our LulzBot 3D Printers it has always been easy to get customer support on the line and walk through the issues at hand,” Laurita said. “Our LulzBot 3D Printers have been running almost continuously for the last year.”

The benefit of LulzBot 3D Printers to Cascade Lacrosse’s product development has been tremendous. Ideas are generated faster and within a cost-effective framework. That speed is key with lacrosse being one of the fastest growing sports in the United States.

Faster turnaround times and improved flexibility help the company retain the customer focus that has helped them succeed as a U.S. manufacturer for over 30 years. As Cascade Lacrosse continues to provide superior products, LulzBot 3D Printers remain the choice additive manufacturing solution in their prototyping efforts.

“The flexibility you have with the modular tool heads, the size of the build plate, and the quality of the prints you get make the LulzBot 3D Printer a great value,” Laurita said. “Once we had our first LulzBot 3D Printer in-house, it was easy to justify to our management team getting a second.”

Explore Other Prototyping Applications with LulzBot 3D Printers ➡