See the LulzBot BIO product page! ➡ Click HERE

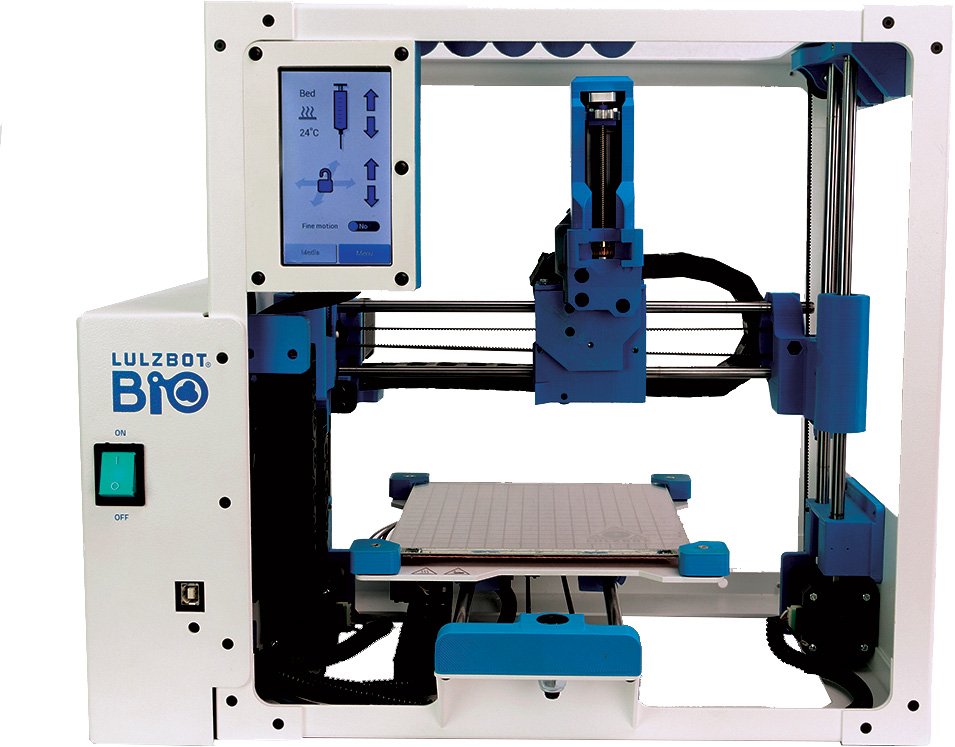

The LulzBot Bio is the first FRESH™ Certified 3D printer in the world.

3D Printing a Human Heart

Bioprinting has a bright future as the solution to the shortage of organs for donation. Research has quickly come close to 3D printing actual organs that could be transplanted into a human. In this issue specifically, research related with CMU, or Carnegie Mellon University, showed that their unique bioprinting setup and procedure was able to print a full-sized heart made out of alginate. Overall, FRESH displayed that these same results are possible with the LulzBot Bio 3D printer.

Scan, Convert, and Bioprint!

Bioprinting is a vast advancement of 3D printing that uses biomaterials making it possible to print soft materials that can resemble tissues. Scanning, segmentation, and printing are the three steps in bioprinting. The first step involves obtaining a 3D scan of the heart that contains several slices. A computerized tomography (CT) scan, a magnetic resonance imaging (MRI), a transthoracic echocardiography (TTE), or a transesophageal echocardiography (TEE) are specific scan types that can do this. They give high contrast, low noise, adjacent structures, and high spatial resolution. The second step, segmentation, comprises of creating patient-specific areas within the organ for printing. A standard tessellation language (STL) file is made from the scan and eventually exported into a computer-aided design (CAD) software. Through exporting, it is important to smooth the structures and clear up any unneeded data from the raw imaging. The last step is determining the print path and performing the actual print. There are numerous printers used in the bioprinting field. They range from stereolithography, powder bed fusion, material extrusion, and material jetting.

FRESH™ Explained

Carnegie Mellon University gave us a FRESH approach to their newly made heart. FRESH stands for freeform reversible embedding of suspended hydrogels. Precisely, this strategy supports crosslinking with pH changes, divalent cations, and UV light. It also lessens the effects of gravitational forces and creates the ability to print soft materials without losing their structure. The material that was printed was 4% low-infill alginate bioink. With previous tests, this proved to show the best strength against tension. Basically, they used their 3D printer to extrude alginate out of the syringe, through a 6-inch, 12-gauge needle, and into a container full of LifeSupport hydrogel. This print took on the shape of the original heart scan while being suspended in the support bath. Additionally, it is important to note that the LulzBot Bio is the first FRESH certified 3D bioprinter in the world.

The Future of Organ Engineering

Ultimately, their print was a success! They constructed two whole hearts and one-half heart to visualize the interior cavities. It was found that there was no change in fidelity or integrity of the two full hearts. Also, it wasn’t measured exactly, but the hearts appeared to be the same size as the original scan. Other prints also portrayed that the vessels work and were able to transport blood-like glycerol. This was the first full-size human heart printed using FRESH. However, there is still some work to do before we are qualified to transplant 3D printed organs. The presented research established the capabilities of printing with FRESH and alginate bioink. The printed heart wasn’t fully functioning and is still required to anastomose to host vessels before it can be transplanted.

Although, the FRESH hydrogel was able to suspend a 3D heart made of soft alginate which resembles real cardiovascular tissue. Being FRESH certified, the LulzBot Bio is fit to construct the same full dimensional heart made of 4% low-infill alginate. Overall, this research confirmed FRESH as a useful strategy in discovering how to 3D print organs in turn aiding to the limited supply of donated organs.

See the LulzBot BIO product page! ➡ Click HERE

About LulzBot

Your Imagination Built by LulzBot®. LulzBot was founded in January 2011 in Loveland, Colorado. In 2019, LulzBot became part of FAME 3D and is currently headquartered in Fargo, North Dakota, USA, where we develop, manufacture, and support the award-winning line of LulzBot 3D Printers for rapid prototyping, additive manufacturing, educators and hobbyists. For more information, visit LulzBot.com.